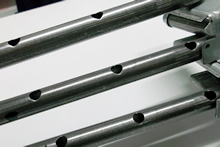

Gas rails

|

|

GS uses only raw materials and first class components with certified quality provided by a network of suppliers and selected according to the best ratio quality/price/innovation.

GS quality control system always monitors all stages of the process to the final test. In particular, a double test to measure the internal pressure loss is done automatically on 100% of the products, to detect any defeat on the finished product.The GS sales and technical departments are able to guarantee adequate support both in planning stage, in prototype construction and after sales service.

GS uses high quality electro zinc-plated connectors and aluminium-coated steel pipes; that offer maximum protection against oxidation and thermal shock. This technology is now widely well-known and offers the following advantages:

- Complex shapes always faster and cheaper

- Mechanical fasteners always secure and compact

- Quick and accurate mounting of the gas valves

The use of pipe with round section and with suitable thickness allows optimization of subsequent assembling, great flexibility in design and good saving, compared to other alternatives.

The connection of the gas rail can be achieved both through edge processing or sealing gasket and through connectors welded directly to the pipe tip.It is also possible to apply fixing brackets in zinc-plated or aluminium-coated steel sheet directly to the gas rail, to ensure easier assembling operations.

The components MOULD is made internally by GS, also able to design and manufacture the moulds needed for the production of brackets. In order to ensure proper maintenance of the machinery and to reduce problems, GS has an highly specialized workshop, able to provide the necessary service in complete autonomy.

GS workshop has a fundamental role in prototyping and developing new projects. In association with its technical department and some external partners, GS is able to design and manufacture equipment of various kinds.